The ICT Group has always believed in innovation as a means of finding new and distinctive solutions to satisfy both customers and consumers: innovation in product, process and strategy. Innovation takes place by taking full advantage of the entire eco-system, thanks to constant dialogue with customers, consumers and business partners, fostering continuous research in quality, in the features of paper and its converting. This leads to new products and new logistics and management processes, constantly undergoing analysis and improvement. Innovation at ICT is deeply rooted in the company’s mindset – it does not follow current trends but pursues its own ideas. It is successful innovation, as evidenced by the many patents obtained and appreciated by the market.

INNOVATION AND DESIGN

Successful solutions: cutting edge and able to manage change through innovative projects

ICT Poland is the most technologically advanced European site in the industry. To confirm this leadership, in 2010, a fully automated warehouse was implemented. As a result, error probability was significantly reduced, the level of safety increased, and the risk of damaged goods minimised.

The warehouse, that has been enlarged in 2017, has now a height of almost 35 metres, which makes it one of the tallest buildings in Lubusz. The warehouse operates 24 hours/day.

Service is guaranteed by 14 vehicles depositing and unloading goods on 12 storage levels. The storage area, which is always available, allows for rapid adaptation to changes both in production and customer orders.

More than 90000 pallets can be stored, which if arranged one in front of the other would have a length of over 100 kilometres.

The storage area is about 23000 m2, equal to 3 football fields or 123 volleyball courts. This integrated solution joins the production department to the warehouse so that pallets can easily be transferred to approximately 200-metre-long conveyor belts.

The warehouse can receive about 300 pallets per hour. Goods are loaded at a speed of 460 pallets per hour so that more than 224 trucks can be filled per working day.

It was the year 2000 when tissue manufacturers began to use a technology that was called deco-embossing, a process that involved both laminating with glue and embossing. Thanks to this process it was possible to create two layers of decoration, a base pattern with a decorative pattern on top. ICT wanted something more: the same result, but without the glue, in line with the group’s constant commitment to quality and sustainability. It was a step change for the industry. Pilot tests were carried out and inspiration was found in the metal industry, with a partner that was capable of engraving heat treated metal. The project involved four different players: ICT Marketing, with a set of captivating decorations, ICT research and development, who led the project, a machinery manufacturer and an engraving specialist. The result was a knurling process capable of both ply-bonding and decorating the sheet. Many ICT products have been using the technology since, and it is particularly appreciated by consumers on the European market. ICT has patented the technology.

Converting Production System, or CPS, is an in-house system created by ICT to manage its production process in converting parent reels to finished products, with the aim to fully satisfy customer expectations in terms of quality and service. The system is totally integrated, and is based on five pillars: Safety, Efficiency, Quality, Environment and Waste. Line operators and team leaders are engaged in a daily meeting where scope for improvement and innovation in each pillar is openly debated, and where each team member is encouraged to report potential issues or incidents and submit their ideas to make the workplace better and more efficient . Team leaders then hold a weekly meeting with management to discuss the suggestions collected and implement actions. A monthly meeting is dedicated to discussing predetermined performance indicators. Part of the CPS is also a process of lifelong learning for operators that enhances their skills in all aspects of their work. The CPS system has already had a very significant impact on both safety and efficiency, and makes work for line operators more engaging and gratifying, in line with ICT’s commitment to its people and their wellbeing at work.

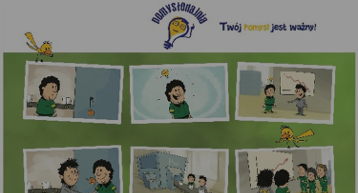

By respecting the creations of our brains and putting them to life, we create at ICT Poland a competitive advantage and bravely look into the future. The Ideas Incubator is a programme aimed at making use of the ideas of all the employees of ICT Poland. Perhaps, after watching the recording, you will ask yourself this question: When did you last implement your idea?

Since 2005, ICT Poland has been adopting principles and methods developed within the area of Lean Manufacturing. An effective image of the Lean Manufacturing philosophy is represented by a temple open to everyone, the components of which are described below

- The Teams: 1+1=∞

Together, we are able to achieve more: teams play a crucial role in the improvement process. When we act alone, we are unable to match the quantity and quality of ideas that can be generated by a team.

- The 5S system

The 5S come from five Japanese words that start with the letter S and refer to an integrated view of the workstation organisation:

1S – separate the useful things from the needless things and manage the latter

2S – visually arrange the necessary elements so that they can all be found at all times and be put in their assigned places

3S – keep your workplace tidy in order to identify new problems

4S – define the standards for the systematic implementation of the first three Ss.

5S – continuously improve, increasing the level of complexity

- SMED (Single Minute Exchange of Die)

Teamwork cuts down on machine downtime for size changes since it optimises the work to be done and establishes the operators’ work standard.

- TPM- Total Productive Maintenance

The aim of TPM is to make improvements in system maintenance so as to have zero accidents in the workplace, zero machine faults and zero production shortcomings. This allows operators and maintenance workers to focus on system improvement activities, instead of having to spend time managing problems along the way.

- Skill Matrix - matrix of employee skills

The Skill Matrix is a tool for encouraging the growth of human resources and for planning the training courses needed to achieve specific skill levels as well as high and constant performance during all work shifts.

- QES

The integrated management QES System, “Quality, Environment and Safety”, conforming to standards ISO 9001, ISO 14001, OHSAS 18001, IFS PC, supplements the Lean Manufacturing system of ICT Poland. The synergy between QES and 5S is a guarantee for continuous improvement.

For some time now, the Lean Manufacturing system has been integrated into all the converting production units of ICT Group.

Through a website, we have been able to develop a tool with which we can measure the level of knowledge of all our operators in terms of risk prevention.

Our operators can access the page with a password to answer a questionnaire on safety in the workplace. If their skills prove to be inadequate, they will receive appropriate information and training.

This initiative was very well received by all of the staff, and most people filled out the questionnaire obtaining excellent results.